Produits phares

Fly Ash Ultra Fine Powder Mill_Ultra fine grinding

2018-11-8 Fly ash ultra fine powder mill can process the fly ash powder in the range of 300 mesh to 2500 mesh, after be grind into the fly ash powder, it can be used in many areas as a filling materials, such as: cement powder, activated carbon making and so on. And the capacity of the fly ash grinding mill can up to 45 tons per hour. To be honest, compare with other nature materials, the fly ash is

Contact

XZM Ultraifne Mill For Fly Ash Processing

2021-5-20 The activity of fly ash can be improved by grinding, so that it can be used in cement, concrete, wall materials and other building materials with a larger dosage. The market value of ground

Contact

ultrafines mill ash fly dystrybutorydowody.pl

ultra fine grinding mills for flyash hometbmueblerias.mx. Flyash Grinding The ufg mill®, a dry fine grinding media mill when operated in closed circuit with a high efficiency air classifier is capable of

Contact

Ultrafine Mill And Material Fly Ash pizzalesartistes.fr

Raymond Mill Ultrafine Mill Vertical Roller Mill Coarse . Ultrafine Vertical Mill Fineness mesh Capacity 10-50 t/h Raw materials Calcium carbonate Pebbles coal slag bauxite coal gangue bentonite Raymond

Contact

Ultrafine Fly Ash Mill ergonomiabudowlana.pl

ultrafine fly ash (20%) 0.39 118 22.7 27.4 42.7 59.4 cement (80%) ultrafine fly ash (20%)+1,2 mass.% PC 0.39 240 14.3 40.1 60.7 65.7 It should be noted that the use of ultrafine ground fly ash with

Contact

Ultrafine Fly Ash

2010-5-22 The ultrafine fly ash continues to increase the strengths and decrease the permeability as the concrete continues to cure beyond 28 and 56 days. This benefit was shown on the I-10 project through additional testing as the permeability dropped on

Contact

ultrafine fly ash mill

Experimental studies on pulp and stone mill. 4 of the fly ash The condensed species included K, Na, S and Cl Their mass fraction was higher in the pulp mill sludge than in the stone mill sludge and. Get

Contact

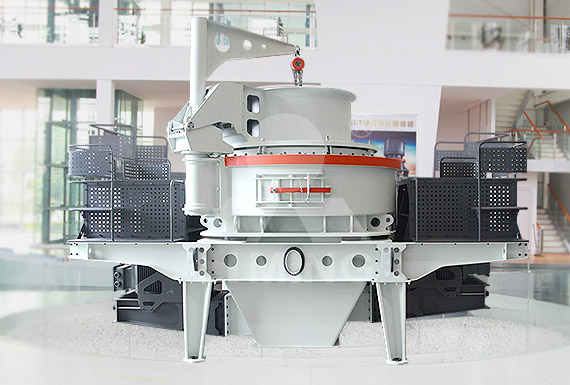

What is the grinding mill for 400 mesh-2500 mesh ultra

2022-3-5 What are the specific coarse ash and fly ash grinding mill equipment? (1) GKH series ultrafine mill. GKH series ultra-fine ring roller mill has been pursued by the majority of customers

Contact

Effect of ultrafine fly ash on mechanical properties of

2014-1-31 The effect of ultrafine fly ash on the compressive strength development of high volume fly ash (HVFA) mortars at 7 and 28 days is discussed here. The ultrafine fly ash content of 8% was

Contact

Ultrafine ash aerosols from coal combustion:

2007-1-1 1.. IntroductionPulverized coal fly-ash aerosol size distributions appear to possess three distinct modes .These include a coarse fragmentation mode with particle diameters greater than 5 μm,

Contact

XZM Ultraifne Mill For Fly Ash Processing

2021-5-20 The activity of fly ash can be improved by grinding, so that it can be used in cement, concrete, wall materials and other building materials with a larger dosage. The market value of ground fly ash will increase accordingly. Usually, the secondary and tertiary fly ash are mainly ground to a level of ash. At present, fly ash has been ground in

Contact

Ultrafine Mill And Material Fly Ash pizzalesartistes.fr

Raymond Mill Ultrafine Mill Vertical Roller Mill Coarse . Ultrafine Vertical Mill Fineness mesh Capacity 10-50 t/h Raw materials Calcium carbonate Pebbles coal slag bauxite coal gangue bentonite Raymond Roller Mill Fineness 80-325mesh Capacity 1-50tph Raw Material Marble granite fly ash kaolin calcium carbonate slag bauxite glass Ultra Fine Grinding Mill THE EFFECT OF HIGHK DVOK I HJKOV THE

Contact

ultrafine mill and material fly ash

the fly ash as the sole cementing material Cross 2005 In addition to providing an indication of the mineralogy and reactivity of the fly ash the calcium content is also useful in predicting how effective the fly ash will be in terms of reducing the heat of hydration Thomas 1995 controlling expansion due to alkali silica reaction Shehata. Chat

Contact

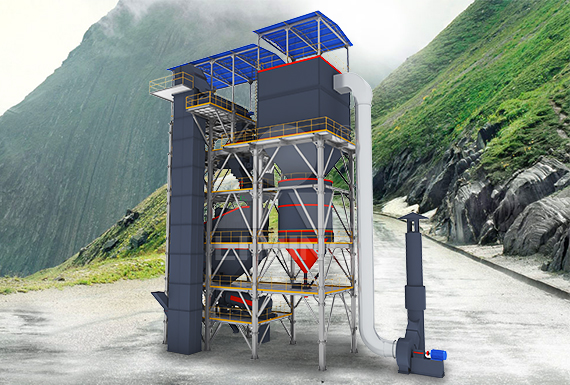

fly ash ultrafine grinding mill fly ash ultrafine powder

fly ash ultrafine grinding mill fly ash ultrafine powder grinding mill. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. 250tph limestone crushing line in Kenya. 250tph granite crushing line in South Africa. MCC 120tph granite crushing line in Zimbabwe.

Contact

Fly Ash Ultrafine Powder Multiroll Mill Crusher

2021-6-9 Jan 08 2018 description ultrafine powder mill leads the fly ash industry to move forward a new direction group news 01082018 as we all know fly ash is the largest type of industrial waste emissions accounting for an absolute proportion of all coalfired byproducts and with the environmental requirements of various countries around the world the.

Contact

ultrafine fly ash mill

Experimental studies on pulp and stone mill. 4 of the fly ash The condensed species included K, Na, S and Cl Their mass fraction was higher in the pulp mill sludge than in the stone mill sludge and. . ultra fine fly ash grinding.

Contact

Ultrafine Fly Ash MillSand Classifier South Afri

T130X Reinforced Ultrafine Mill mpl Machinery T130X reinforced ultrafine mill is a new chemicals and mining iron oxide, slag, clinker, chemical fertilizers, compound fertilizers, fly ash

Contact

Mill Fly Ash Ultrafine Powder abac.pl

Grinding Mill Stone Grinding Machine Crusher Stone Crusher. Ultrafine Vertical Mill are suitable for huge capacity producing widely used in grinding non flammable and non explosive materials under 7 the Moh s hardness such as quartz feldspar calcite talcum barite fluorite iron ore copper ore quartz especially for slag cement clinker zircon sand fly ash and carborundum coal etc more >>

Contact

(PDF) Pulp and Paper Mill Fly Ash: A Review ResearchGate

2019-8-14 Particle size distribution of pulp and stone mill fly ash (PPFA). PPFA particles observed with SEM at 50 µm and 10 µm. Summary of the typical oxide compositions of PPFA.

Contact

Utilization of mill tailings, fly ash and slag as mine paste

2021-11-22 Fly ash and slag may have different physical properties depending on the coal source and burning efficiency of power plant, metal extraction process, respectively. The bulk of the fly ash particles fall in a size range of 10–80 µm and the maximum size of fly ash particle may be up to 100 µm,. Coarser slag particles fall within the size

Contact

Fly Ash Ultrafine Powder Multiroll Mill Crusher

2021-6-9 Jan 08 2018 description ultrafine powder mill leads the fly ash industry to move forward a new direction group news 01082018 as we all know fly ash is the largest type of industrial waste emissions accounting for an absolute proportion of all coalfired byproducts and with the environmental requirements of various countries around the world the.

Contact

Ultrafine Fly Ash

2010-5-22 The ultrafine fly ash continues to increase the strengths and decrease the permeability as the concrete continues to cure beyond 28 and 56 days. This benefit was shown on the I-10 project through additional testing as the permeability dropped on

Contact

fly ash ultrafine powder multi-roll mill

Keywords: vertical milling machine; grinding system; fly ash. Abstract: A new ash China,Coal-fired thermal power plant total annual emissions of fly ash increases every year,In 2010 about 300 million At the same time, the new mill roll material and quick New

Contact

mill fly ash ultrafine powder visueelvertaler

The Price Of A Set Of Fly Ash Ultrafine Grinding Mill System. The Price Of A Set Of Fly Ash Ultrafine Grinding Mill System. 2020-05-04 10:50; HCM; Fly ash belongs to industrial solid waste. What kind of grinding mill can be used to grind fly ash? According to the present production situation of fly ash, Guilin Hongcheng provides special

Contact

Mill Fly Ash Ultrafine Powder abac.pl

Aluminium Hydroxide Ultrafine Powder Extracted from Fly Ash. Al OH 3 ultrafine powder was extracted from fly ash with the method of dispersing agent carbonizating Fly ash is activated by the method of sintering with limestone so the inert mullite can be convert into C12A7 which can be dissolved in Na2CO3 liquor The conversion of β C2S to γ C2S is accompanied by an increase in volume and

Contact

ultrafine mill ash calcium,

ultrafines mill ash fly oriflamekromeriz. ash calcium ultrafine mill pelsdieren ultrafine fly ash millcoal mill with classifiers XiMiT The parent ash is passed through a classifier where the coarse particles are removed and the Ultrafine fly ash can be added along with the normal dosage of fly 3000 Mesh Calcium Carbonate Ultrafine Mill ultramill.

Contact

Free Full-Text Pulp and Paper Mill Fly Ash: A Review MDPI

2019-7-21 The continual growth of pulp and stone industry has led to the generation of tremendous volumes of fly ash as byproducts of biomass combustion processes. Commonly, a major part of it is landfilled; however, updated environmental regulations have tended to restrict the landfilling of fly ash due to rising disposal costs and the scarcity of suitable land. The pulp and stone industries are

Contact

Sustainability Free Full-Text Pulp and Paper

2019-7-21 The continual growth of pulp and stone industry has led to the generation of tremendous volumes of fly ash as byproducts of biomass combustion processes. Commonly, a major part of it is landfilled; however, updated environmental

Contact

Fly Ash SpringerLink

2017-12-9 Fly ash accounts for 75–85% of the total coal ash, and the remainder is collected as bottom ash or boiler slag (Fly Ash and Coal Conversion By-Products 1988). Fly ash produced from thermal power plants is a variable material because of several factors. These factors include (Siddique and Khan 2011): (i) type and mineralogical composition of

Contact

Pulp and stone mill wastes: utilizations and prospects for

2021-4-29 The successive development in the pulp and stone mill has headed to the release of a large quantity of fly ash (Fig. 6e) as a result of combustion processes of waste biomass. The elemental composition survey on fly ash from pulp and stone mills revealed that the ash consists of different minerals predominantly iron oxide, silica, and alumina.

Contact